Screening Out Fines From PET Flakes...

Texas Shaker – Shakes Grain Handling Industry

Renowned for its flagship products, the Texas Shaker grain cleaner and Slipstick horizontal motion conveyor, Triple/S Dynamics is winding down its 125th anniversary year and winding up the transition to new ownership that promises to build on the traditions of the Sullivan family and the founding trio of the Sutton, Steele, and Steele boys in 1888.

In that same year, Thomas Edison still was introducing the novelty of electricity to the nation. However, Henry Sutton and his colleagues, Walter and Edwin Steele, were toying with electric fields, airflow, and vibration for separating dissimilar materials. Called Sutton, Steele and Steele, it was one of the first companies to incorporate in Dallas, TX. The company produced electrostatic separators for improving agricultural and mineral products and other electricity-driven equipment.

Recognized by the Franklin Institute for its material handling advancements as early as 1900, the company began to focus its business on making equipment that would separate dry solids with a gravity separation process.

1950s Dynamics

While Sutton and the Steele brothers were building their business, Professor Gustave Overstrom was refining his technology for material screening. Each company had its eye on the other as being complementary. Their businesses consolidated in the 1950s, with the operation remaining in Dallas and the Overstrom Company operating in Alhambra, CA.

A young engineer named Jim Sullivan was hired in 1956 to work in the laboratory and quickly developed a small gravity separator, the D-135, a variant of which is still made today.

In 1965, the widows of the founding partners promoted Sullivan to manage the company and then agreed sell it to him in 1968. That launched the multi-generational Sullivan era for the renamed company Triple/S Dynamics.

“I remember our family moving to Alhambra, as Dad was shutting down operations there, in preparation for consolidating the company back in Texas,” said Jeff Sullivan, who has provided recent corporate leadership to Triple/S Dynamics and remains its president under the current ownership structure.

The Cork Really Popped

“Jim is just an old-fashioned entrepreneur and did whatever he could to make a go of the place,” said Jeff. “He compared the business to a cork held underneath the surface of the water, and when you pull your thumb off, it would pop right up. He was tireless and pursued every lead and every avenue.”

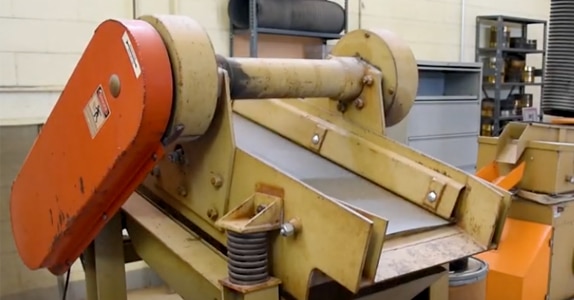

The cork popped up in the 1960s with the development of the Texas Shaker, a veritable “Texas-sized” vibrating screen. “It was king of the hill, when they were building tons of export elevators in the 1970s. The Slipstick, which is another big product of ours, got started in the 1970s and took off in the 1980s. Along the way, we built wire-chopping systems, and all along, we built the Sutton line of gravity separators,” said Sullivan.

The Texas Shaker Company

When the Texas Shaker first was developed, Sullivan said it was “the only game in town for high-capacity, single-unit screening. It quickly got built into very large sizes, which made it particularly good for bulk handling facilities like grain elevators. A lot of people thought of us as the Texas Shaker company, because it was our face.

“After the Carter 1980 grain embargo, we did not sell many Texas Shakers to grain elevators. We redesigned it to call it our QC or quick change model.”

“There are other competitors out there now who build large vibrating screen machines. I don’t know of anyone who builds a similar unit larger than the big Texas Shaker, but it is still an excellent product in the market for sizes ranging from quite small to very large.”

Sullivan said a very large Texas Shaker unit will handle up to 40,000 bph. Smaller units are built for seed companies, chemical companies, and any process that needs a separator as low as 1,000 pounds per hour.

Sister Act

A sister product at Triple/S Dynamics is the Slipstick horizontal motion conveyor. Sullivan said, “The Slipstick is a horizontal motion conveyor and it works like the old parlor trick with the table cloth. If you pull it quickly everything stays on the table, but if you pull slowly it all comes off.

“That is what a horizontal motion conveyor does. It moves slowly forward and then it snaps back. It shuffles material along, without pitching it. A normal vibratory conveyor throws things up in the air and forward, and this just shuffles things along,” he explained.

“As it turns out, the Slipstick was just what the customer ordered in the truest sense of the word. It took a while to catch on, but the cereal industry realized it was just what it needed.

“We got it into the food business, in cereal handling, and a particular quality of it was that it did not degrade material,” added Sullivan. “When you put cereal flakes in it, at the other end, there were no extra fines in it. The product was not damaged. This was one of those iconic moments for us. We were talking with a customer who put one in a test facility, and that customer said this thing doesn’t break their flakes. We asked if that was important to them. That customer said that is the number one consumer complaint.

Corporate Philosophy

“We really strive to be the best. We strive to build the best equipment using up-to-date and modern methods, constantly refining our design and capability,” explained Sullivan. “We are absolutely committed to customer success.”

“We will do anything we can to correct a problem, if there is one. We are absolutely dedicated to keeping our word to our customers. Those are the two driving forces. We want to build the best equipment that we can. We want to build the best equipment available in the world, and we want to stand behind it 100%.”

That sums up the corporate philosophy of Triple/S Dynamics, according to Sullivan, and that is not likely to change much in the near future, if it is up to Ned Thompson.

Thompson is the CEO of KMC Global, Kalamazoo, MI, a firm that owns seven companies, two of which manufacture products similar to the product line of Triple/S Dynamics. One is PRAB, Inc., a leading manufacturer of material handling, chip, and fluid management systems. The other is Hapman, Inc., a manufacturer of conveyors and material handling equipment for the processing industries.

Thompson said KMC Global acquires companies that fit a corporate culture representing good people and good products. “We had been looking at Triple/S Dynamics for a long time, and we had a chance to meet the Sullivans and quickly decided we wanted a relationship with them.”

“I have high praise for Jim and Jeff Sullivan, whose family has a long tenure with the company back to the 1950s,” said Thompson. “They have integrity and a work force that is uncommon today. They have employees who go to work and never leave the company.

“As for the future, we would like to see Triple/S Dynamics renew its relationships with the industries that had been their market in the past, such as the grain industry.”

Recent Acquisition

Sullivan said his family has had no qualms about their company being acquired by KMC Global, which occurred in 2011. “We looked at the horizon and we thought there is some benefit in being allied with another company. That put us in the position of saying we are either going to buy, merge with, or acquire another company,” he said.

“We decided that we were more engineers and salesmen than we were corporation builders. Of those three options, we decided that selling to a compatible partner was a good, long term strategy, and that was our thinking behind that,” he said.

“You hear horror stories all of the time of things that happen, when a company gets acquired, or when there is a merger. This has been a joy, and I say that with utter sincerity. I could not have asked for a better partner than we have in KMC Global and in Ned Thompson,” added Sullivan.

-2013 Grain Journal (Mov/Dec)